PT. Environeer

031-99858624 (Surabaya), 021-8935060 (Jakarta)

Conveyor Frame Material

Conveyor is a machine which function is to move things or material from one place to other places. You will save more time and manpower by using a conveyor to move things. Other than that, the use of conveyors also guarantees quality and quantity of production output.

Conveyor frames are an integral part of modern material transportation systems that facilitate the efficient movement of goods or materials from one point to another. The materials used in the construction of the conveyor frame have a critical role in determining the reliability, durability, and performance of the entire system.

Conveyor consists of several parts that functions differently. One of the important parts of a conveyor is the frame. Frames on a conveyor can be made using different kind of materials. Besides to support the objects being moved, variants of conveyor frame’s material are also take part in defining the quallity and strength of the conveyor itself.

Below are some of conveyor frame’s materials and the type of industries which uses them:

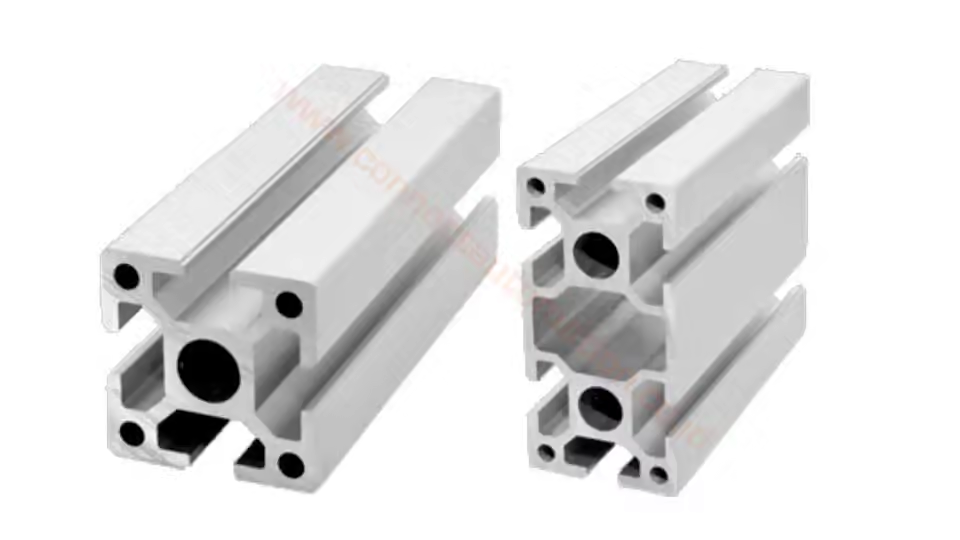

1. Aluminium Profile

Aluminium profile is one kind of aluminium which has a bar shaped with varieties of slots. Aluminium profile based conveyors are really common and used for most industries. Not only for conveyors, aluminium profile can also be used to make workstations, safety guardings, enclosures, etc.

Aluminium profile based conveyors are always so easy to assemble for its knock down system. Conveyors that uses aluminium profile are really compatible with plastic packaging industries, injection molding industries, cosmetics or any products that are light to medium-light duty. However, aluminum is less suitable for use in chemically aggressive environments.

Belt and roller type conveyors are generally uses aluminium frames. Here’s a few types of conveyor belt and its specifications:

PVC Belt Conveyor

Making of conveyor of type conveyor belt uses aluminium profile for its frame. For the belt, it uses a heat-resistant PVC belt that supports up to 70 degree celcius. Shapes of this type of conveyor is limited to straight and inclined and declined. This conveyor uses motor to move the belt.

Oily Belt Conveyor

This type of belt conveyor is used for oily production output. Its belt’s surface have more textured compared to the previous PVC belt. Making conveyor for automotive industries uses oily belt conveyor for their production output such as spare parts.

PU Belt Conveyor

Polyurethane or PU for short, can be used as belt material on conveyors. Especially for industries that requires food grade material for their production machineries. Therefore making conveyors of this type are massively used in food and beverage industries.

If you're looking to improve your production efficiency but still don't know whichconveyor is right for you, we recommend reading our tips on choosing belt conveyors and roller conveyors!

Roller Conveyor

Aluminium profile can also be used for roller conveyor’s frame. Not only its frame, its roller can also be made out of aluminium. Making this type of conveyor can include the use of drive motor and without drive motor. Making this type of conveyor can be used to move goods that has already been packaged inside a box (or any other packaging).

2. Stainless Steel

Stainless steel or usually called rust-resistant steel. This material is commonly used for kitchenwares. This is due to many recipe’s ingredients that are acidic and therefore could trigger corrosion on kitchenwares. This is why the material is a solution to the issues.

Not only for above matter, almost all food and beverage industries and pharmaceuticals uses this material. Products that come in direct contact with human body, be it for consumption or applied on human skin, are required to use stainless steel based conveyor frame.

Making stainless steel based conveyors are even sturdier and stronger compared to those with aluminium based frame conveyor. Not just sturdier, this type of conveyors are more durable and rust-resistant.

Modular Belt Conveyor

Modular belt conveyor consists of multiple individual plates that are assembled together into a whole belt. These plates commonly used hard plastic and usually comes with slippery surface. This type of conveyor uses knock down system. If damages occurs on the belt area, repairation for this conveyor type is easier than conveyors that uses PVC or PU for the belt.

Making this type of conveyor mainly used for pharmaceuticals and food and beverages (F&B) industries. Modular conveyor are much more dynamic compared to PVC or PU belt conveyor. It can fit the size of rooms it’s used in easier.

Want to know about the application of modular conveyor?

3. Steel

This material commonly used in constructions. Steel can also be used for conveyor’s frames. Steel based conveyor frames are compatible for mining industries. Steel based conveyor supports heavy-duty usage or industries which production output reaches 50kg to 100kg per product output.

The choice of frame material for a conveyor is highly dependent on factors such as workload, operational environment, and application-specific needs. The combination of the right material and good design will provide optimum precision and performance of the conveyor system, which in turn will help improve operational efficiency and increase production in various industries. Before selecting materials, it is always important to consider the specific standards of the desired requirement to ensure the long-term success of the conveyor system.

Connect Automation, the first choice of conveyor solutions for your industry. As a leading conveyor manufacturer in Indonesia, we deliver superior quality and competitive pricing. Trust the sustainability of your operations to us, because we not only provide conveyors, but also the best solutions to improve efficiency and productivity in your industry. Order now!

About Us

Connect Automation specializes in providing automation solutions, including conveyor systems, to improve efficiency across various industries. The company delivers cutting-edge technology to help organizations automate tasks and optimize workflows. Connect Automation helps businesses reduce manual efforts, boost productivity, and achieve better outcomes. With a customer-focused approach, the company designs tailored solutions to ensure smooth and effective automation transitions for long-term success.

Connect Automation specializes in providing automation solutions, including conveyor systems, to improve efficiency across various industries. The company delivers cutting-edge technology to help organizations automate tasks and optimize workflows. Connect Automation helps businesses reduce manual efforts, boost productivity, and achieve better outcomes. With a customer-focused approach, the company designs tailored solutions to ensure smooth and effective automation transitions for long-term success.

Cikarang Store

Kawasan Industri Jababeka Tahap 1, Jl. Jababeka II D Blok C14L Cikarang, Indonesia (17530)

(021) 893 5060 Google Maps

Kawasan Industri Jababeka Tahap 1, Jl. Jababeka II D Blok C14L Cikarang, Indonesia (17530)

(021) 893 5060 Google Maps

Surabaya Store

Rungkut Industri III, No. 37, Rungkut Menanggal, Kec. Gn. Anyar Surabaya, Indonesia (60293)

(031) 9985 8624 Google Maps

Rungkut Industri III, No. 37, Rungkut Menanggal, Kec. Gn. Anyar Surabaya, Indonesia (60293)

(031) 9985 8624 Google Maps