How Many Industrial Problems Solved Using Conveyors?

What Is Conveyor And How Vital They Are To Industries

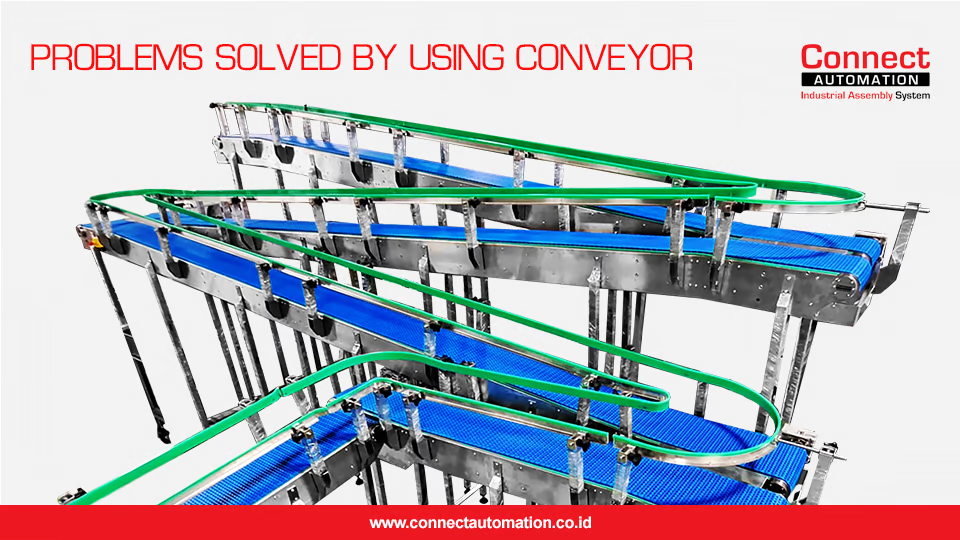

Conveyors are an essential part of many industries. They are used to move materials and products from one place to another, quickly and efficiently. Conveyors can be found in factories, warehouses, and other industrial settings. They play a vital role in the manufacturing process by helping to reduce costs and increase efficiency.

Conveyors come in many shapes and sizes, from large overhead systems that move heavy loads to smaller conveyor belts that carry light materials. The type of conveyor system used depends on the type of material being moved, the weight of the load, and the size of the space available for installation. Regardless of which type is chosen, conveyors can be integrated with various systems to solve many industrial problems.

Here are some industrial issues that can be solved using conveyors.

Product Weight Control

A conveyor can be integrated with an automated weighing scale to check and control goods weight. For example, an automated weighing scale can be put underneath a conveyor belt. Conveyor would stop every time a product gets on top of the weighing scale and gets measured. The goal is to check whether the products satisfy the standard weight range or goes beyond that. A conveyor can also have an automated kicker so every time a product measured beyond standard weight range, the product is automaticall kicked off the conveyor and the next product would be pushed forward onto the weighing scale.

Size Sorting

Conveyor designs can implement certain design to sort products based on its size. An automated sensor can also be placed to check product size in real time. If the product fits into a size category, then a moving guide or a kicker can react to separate that product from the other unsorted products. The product can then be transported into another processing line using another conveyor. This help industries that have different production process for different sized products.

Cooling Line Conveyors

Products that just went through a process involving high temperature heat, can then be cool down using integrated cooling system. These conveyors can use fans to push cold air and another line of fans to suck out hot air produced from the products. For this purpose, you would need to consider heat tolerance and the design for the conveyor that you would use. A modular belt conveyor is usually used because the holes between the modular belt allows for better airflow.

Cardboard Box Erector And Sealer

Most industries uses their own branded cardboard box to ship their goods in. These cardboard box surely needs to be folded up, goods in, then to be sealed. All of this is frustrating if done manually. A conveyor can also be designed to automated this process so your worker don’t have to. Flat cardboard box gets onto the conveyor, folded automatically then comes out ready to be filled with goods. Once you fill it with goods, you can just move them into a sealer conveyor to close and seal the box.

The Palletizers

Conveyors can also be integrated with a robotic hand to organize products on top of pallets automatically. With this integration, you no longer need to stack boxes of products manually and spend more time and labor cost for it. You can just drive your forklift around to pick up the next pallet and into the shipping container you go.

Filler Conveyor

Integrate your product making machine with conveyor so you can save time and cost from filling the packaging one by one. For example if your products are beverages and you have a machine that pumps out beverages into a packaging or container, then you can design your conveyor to move the container underneath the machine, pumps in the beverage and away they go. Empty bottles in and full bottles out just like that.

Connect Automation specializes in providing automation solutions, including conveyor systems, to improve efficiency across various industries. The company delivers cutting-edge technology to help organizations automate tasks and optimize workflows. Connect Automation helps businesses reduce manual efforts, boost productivity, and achieve better outcomes. With a customer-focused approach, the company designs tailored solutions to ensure smooth and effective automation transitions for long-term success.

Kawasan Industri Jababeka Tahap 1, Jl. Jababeka II D Blok C14L Cikarang, Indonesia (17530)

(021) 893 5060 Google Maps

Rungkut Industri III, No. 37, Rungkut Menanggal, Kec. Gn. Anyar Surabaya, Indonesia (60293)

(031) 9985 8624 Google Maps